Recently, my brother’s gun has been failing to fire at times. At this point, I have enough detailed knowledge regarding KWA AR-15 variants that I can diagnose problems without having to disassemble the gun. I knew the problem was being caused by a wiring issue. It wasn’t a short, as the motor wouldn’t even try to spin when the trigger was pulled. It was either a loose connection or pinched wires. Upon removing the gearbox from the gun, I found nothing but a couple moderately pinched wires to indicate a problem. What complicates the matter is that I once installed a MOSFET in my brother’s M16. The MOSFET is meant to generally improve electronic functionality of the gun, by reducing wear on electrical components, adding programability, and more. The MOSFET was adding a variable that I can’t diagnose. It was time to rewire the gun and remove the MOSFET from the equation all together.

My plan was now to remove the trigger assembly and wiring harness all together. I would then swap in my old M4 wiring harness and rewire the gearbox to the rear for an M16 configuration. Since I’d never had to rewire from M4 to M16 configuration, or vise-versa, I had to open up a friend’s M16 to double check the wiring setup. I was pretty sure I knew where everything needed to go, but a quick check confirmed my beliefs. A few solders and a little finagling later, and the rewire was done.

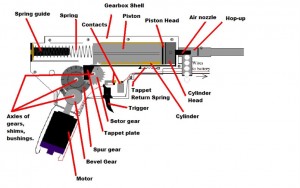

I assembled the gearbox and put it in the gun. I went to test fire it and it got the first shot off, but then suffered what I assessed to be a severe mechanical jam. A mechanical jam is the worst thing that can happen to a gearbox. It means something solid has broken in the gearbox and has become lodged in the teeth of the gears or piston. If you have very strong gearbox components (i.e. gears, piston, etc) this hopefully only means one part is broken. Usually this wouldn’t be a concern, since I have most of the parts for a KWA gearbox in storage.

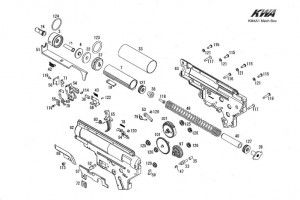

When I opened the gearbox, I released the spring tension and then found nothing wrong. The trigger contact unit was sitting in a strange position, but it reset without a problem. After a second check, I found nothing wrong and reassembled the gearbox. Just as I went to put in the screws to tighten the gearbox, I noticed a little rectangular piece of metal sitting on my desk. When I looked closer I could see the distinctive look of sheared metal on one side. The broken part. I opened the gearbox again and located where it came from. It turned out to be a post that holds the trigger contact unit in place. This is the infamous trigger post that KWA owners with older gearboxes have been fighting for years. They have a tendency to break. It just hadn’t happened to me yet.

After a total of four hours of work. It was finally together and shooting. It’s ugly, and definitely a band-aid, not a fix, but I think it will work for at least one game. People may call me a douchebag when I boast and brag about my ‘airsmithing’ skills, but no one can argue with results like that.